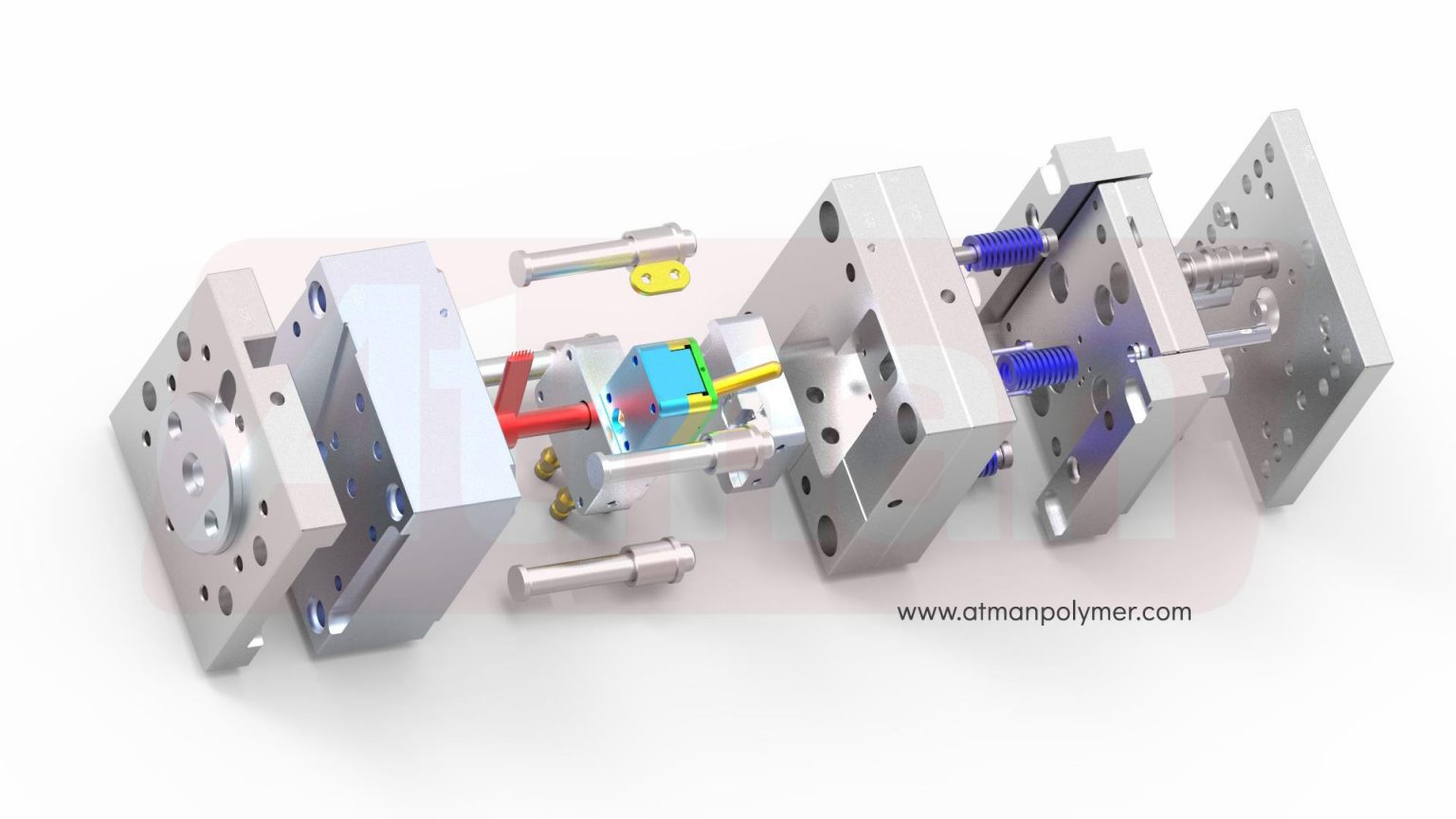

Designing polymer parts is a complex task and includes many factors. In addition to functional and structural issues, issues related to shaping play a large role in the design of the mold of a polymer part. Adherence to the design principles of polymer parts leads to the production of a part that, in addition to being easier to make and assemble, will usually be much stronger in use. If the part is not properly designed to distribute the stresses uniformly throughout the part or has areas where the stresses are concentrated in that part, the mechanical stresses imposed on a part can cause the part to fail and with a high probability of the part from It works. Mold design and injection molding is an advanced, technical and often complex process that requires high precision and scientific knowledge to produce high-quality parts with precise dimensions. Die design and manufacturing engineers must also calculate gate/runner size specifications for proper filling and minimum cycle times, as well as determine the best quenching methods for tool durability over the life of the program.

2 Responses

hi.thanks

thank you