Description

ABS stands for Acrylonitrile Butadiene Styrene. An engineered and amorphous thermoplastic, impact resistant. EBS is composed of three monomers, acrylonitrile, butadiene and styrene, each of which provides specific properties of this terpolymer.

- Acrylonitrile: A synthetic monomer made from propylene and ammonia. This component contributes to the chemical resistance of ABS and its thermal stability.

- Butadiene: A monomer with rubber properties. This component provides the impact hardness and strength to the ABS polymer.

- Styrene: Produced from ethyl benzene by dehydration. Provides this strength and processing capability to ABS plastic.

Ratios can vary from 15 to 35 percent acrylonitrile, 5 to 30 percent butadiene, and 40 to 60 percent styrene. The result is a long chain of crosslinked polybutadiene polystyrene with shorter poly (styrene-acrylonitrile) chains. Nitrile groups from neighboring chains are polar, attracting each other and binding the chains together, making ABS stronger than pure polystyrene.

Styrene gives plastic a glossy and impermeable surface. Polybutadiene causes toughness even at low temperatures. For most applications, ABS can be used between 20 and 80 degrees Celsius (4-176 degrees Fahrenheit) because its mechanical properties vary with temperature. These properties are created by the diffusion of rubber, where fine elastomer particles are distributed throughout the rigid matrix.

ABS features

The most important mechanical property of ABS is impact resistance and toughness. This material has properties between ordinary polymers and engineering plastics. The properties of this material can be described as follows:

- High strength

- Impact resistance, even at low temperatures

- Proper insulation properties

- Weldability and connection

- Good abrasion and strain resistance

- High dimensional stability (strong and stable mechanical over time)

- High level brightness and excellent surface aspect

- Very good resistance to dilute acids and alkalis

- Medium resistance to aliphatic hydrocarbons

- Poor resistance to aromatic hydrocarbons, halogenated hydrocarbons and alcohol

Impact resistance can be enhanced by increasing the ratios of polybutadiene to styrene as well as acrylonitrile.

However, this action changes other properties. Therefore, by changing the ratio of its components, EBS can be prepared in different types.

ABS applications

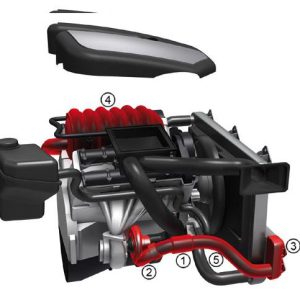

In general, ABS has useful properties in the temperature range from 20 to 80 degrees Celsius. The light weight and injection capacity of IBS makes it suitable for the manufacture of products such as drainage pipe systems, musical instruments, auto parts such as car bumper bars, drug delivery systems, containers for electrical and electronic components, fittings, suitcases, pens, equipment Small kitchens and toys are among the main uses of ABS, including Lego bricks and household and consumer goods. ABS products can include the following:

- Toolbars

- Dashboard components

- Doors and door handles

- Behind the seat, seat belt components

- Control panels

- Compartment (razor, vacuum cleaner, food processor)

- Refrigerator plastics

- Keyboard keyboards

- Pipes and fittings made of IBS are widely used because they are easier to install and do not rot, rust or corrode.

ABS process tips

Injection molding

Dehumidification before injection: If you need to dry and have high humidity, keep it at 80 ° C for 4 hours. Signs of moisture are stripes, streaks or bubbles in the mold and should be dehumidified if any of these materials are observed.

- Melting point (shaping): 210-270 ° C

- Mold temperature: from 40-70 ° C

- Material injection pressure: 50 – 100 MPa

- Injection speed: medium – high

extrusion

- Humidification: 3 hours at a temperature of 70-80 ° C

- Extrusion temperature: 210 to 240 ° C

- Screw design: L / D ratio of 25-30 is recommended