Description

Polycarbonate-polyacrylonitrile alloy is a unique combination of polycarbonate and ABS that can be well formed against the excellent properties of impact resistance and heat resistance. The equilibrium of PC-ABS properties is controlled by the ratio of PC and ABS in the mixture, molecular weight of polycarbonate and additives. Flowability, processability, plating performance and appearance. Heat resistance, impact resistance and strength of thin-walled PC-ABS alloy products are significantly improved compared to ABS.

The ratio of polycarbonate and acrylonitrile butadiene styrene mainly affects the heat resistance of the final product. PC-ABS alloy has a synergistic effect resulting in excellent impact resistance at low temperatures, which is better than ABS or PC impact resistance.

Main features of PC-ABS

General characteristics: PC / ABS is a slightly amorphous, odorless and non-toxic thermoplastic engineered plastic polymer. This material has a relative density between 1.1 and 1.2.

Mechanical properties: Excellent mechanical properties with high impact resistance

Heat performance: Service temperature 60-120 ° C and HDT between 120 to 140 ° C

Electrical properties: Somewhat insulating in nature.

Flame resistance: This material has a high flame resistance.

Resistance to environmental conditions: It has excellent stability in sunlight.

Chemical resistance: It is resistant to acids and oils and is not resistant to alkalis, oxidizing acids, amines and ketones. Dissolves in aromatic chloride and hydrocarbon solvents.

Hydrolysis resistance: It is very sensitive to hydrolysis. At a temperature of 60 degrees in contact with water is prone to hydrolysis and cracking.

Polycarbonate and ABS alloy is a combination of two engineering plastics, polycarbonate and ABS. Properties in polycarbonate which are high heat resistance, strong impact resistance and tensile properties. These properties together with ABS, which has high impact resistance at low temperatures and high processability, provide an alloy with excellent properties. ABS-PC alloy products are commonly found in the automotive, electrical, home appliance, medical and IT markets.

ABS-PC alloy usually has different grades from general applications to flame resistant and impact resistant. This material has excellent performance in applications where impact strength is considered. Polycarbonate-ABS resin has high impact resistance even at low temperatures and has a very high heat resistance.

ABS-PC alloy applications

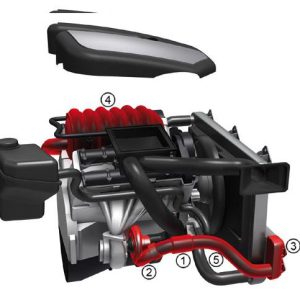

Automotive industry: center console, car tool panel, interior and exterior body parts, trunks

Electronic components and tools: In electronic switches and hair dryers and applications that require impact resistance

Home appliances: TV case, laptop monitor compartment, handheld portable devices, LCD keyboard, keyboard buttons, adapter and charger, mobile phone body.

ABS-PC alloy process technologies:

Pre-forming preparation: Usually at 80 to 110 ° C for 3 to 4 hours

Thermal stability: PC-ABS is degraded by the production of carbon dioxide at 300 ° C. The mechanical properties of this material are significantly reduced at a temperature of 300 degrees. Therefore, the formation time in the temperature range should be considered.

Cylinder capacity: The weight of one injection shot should be 35-65% of the cylinder capacity.

Cylinder temperature: 220-280 ° C

Mold temperature: Normal degrees: 70-100 ° C

Injection speed: slow to medium.

Mold sweetness: 0.5-0.7% and reinforced grades of polycarbonate alloy 0.2 to 0.4%

PC-ABS is capable of printing, plating, bonding, coating and machining. To reduce internal stresses, heat treatment should be performed at 80 ° C for 4 hours.