Description

Polyamide 66 glass fiber (PA66 30GF) is a type of polyamide with high thermal resistance. The strength and tensile strength of this polyamide has led to the use of this material in various industries. High insulation switches and connectors, series and terminals of connectors, power distribution system, cable ducts and connectors, contactors and power switches, windings, circuit breakers, programmable logic controllers are mainly made of polyamide 66 with fiberglass .

Polyamide 66 fiberglass is formed by extruding polyamide 66 fiberglass and polymer resin by extruder. These granules are processed at a process temperature of 260 to 300 ° C.

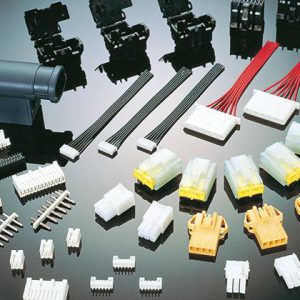

This polyamide has special thermal, mechanical, physical and electrical properties. High mechanical flexibility combined with good toughness of this grade of polyamide. Leads to a wide range of applications in consumer goods and industrial products. These are primarily applications that require high mechanical properties that are often replaced by plastics in materials such as metal or wood. You can see an example of the images in which the polyamide 66 compound is used below.

Features of glass fiber reinforced polyamide 66

Fiber Polyamide 66 or Nylon 66 is a glass fiber reinforced polyamide. This nylon has excellent physical and mechanical properties. The salient properties of this material are:

High strength

High toughness

Creep resistance

Dimensional stability

Fiberglass 66 polyamide is more widely used among engineered plastics used for long-term applications under load than non-reinforced nylon 66. The physical and mechanical properties of this polyamide modified with 30% glass fibers make it suitable for use in areas that are exposed to high static loads in the long run.

Because in some cases fiberglass has a certain abrasion effect on high friction surfaces, Nylon 66 fiberglass (Nylon 66 GF30) is not suitable for applications subject to friction.

Fiberglass 66 polyamide (Nylon 66 GF30) in combination with black additives provides UV protection in applications where resistance to harsh weather conditions and sunlight is required.

Applications of 66-fiber polyamide

Applications of 66-fiber polyamide can be mentioned in the following industries:

Transportation

Electronics and electricity

Construction and building

packing

The main products that are produced with polyamide 66 compound are: alkaline dry battery pad, motorcycle helmet, office equipment case, chairs, skate body, fishing rod, etc. This polyamide can also be used as a material with Ability to turn on parts such as gears and plates.

Glass fiber polyamide process technologies

Nylon 66 melts at 262 ° C. In addition to high thermal stability, polyamide 6.6 has high hardness, abrasion resistance and high strength. This material is often used in injection molding. If the humidity is more than 0.2%, drying at 80 ° C for 16 hours is recommended. If the material is exposed to air for more than 8 hours, drying in a vacuum oven at 105 ° C for more than 8 hours is recommended.

The following process conditions can also be considered as the formation conditions of 66 glass fiber nylon:

Mold temperature: 60-80 ° C

Melting point: 250-300 ° C for reinforced grades

Material injection pressure: 75 – 125 MPa (depends on material and product design)