Description

Polyamide 6 (PA6) is formed from the loosening polymerization of caprolactam. Polyamide 6 or nylon 6 (PA6) is a hard, wear-resistant material. It has a better surface and appearance than nylon 66 (PA66). This material is somewhat crystalline, which is a bit of a challenge in forming small pieces. Nylon 6 has a lower modulus than nylon 66 and absorbs moisture faster than nylon 66.

Moisture reduces tensile strength and stiffness and increases elongation. Nylon 6 was produced in an attempt to reproduce the properties of Nylon 66. This grade of nylon is very hard and has a high tensile strength. It should be noted that nylon 6 is created by a unique process called ring polymerization. Polyamide 6 or nylon 6 is also known as polycaprolactam.

It is one of the most widely used polyamides in the world. The melting point of polyamide 6 is 223 degrees Celsius. This material is one of the most widely used materials in engineering plastics and can be used as a suitable alternative to metal. It has somewhat higher impact resistance than polyamide 66, but has lower tensile strength and higher water absorption.

Polyamide 6 is an engineered plastic material that has good strength and anti-wear properties. This polyamide is chemically resistant to oils, gasoline, alcohol, weak acids, dilute and concentrated alkalis. The properties of this material include the following:

Resistance and strength at high temperatures

Good impact resistance, even at low temperatures

Excellent flow for forming all kinds of parts by injection molding

abrasion resistance

Excellent resistance to organic solvents and oils

Fatigue resistance

Limitations of polyamide 66 include high water absorption and poor chemical resistance to strong acids and bases.

Applications of polyamide 6

Polyamide 6 (PA6) has excellent surface properties in appearance. Due to its low viscosity, it is better formed than polyamide 66 (PA66). It has good electrical insulating properties but high water absorption limits its use. It has low dimensional stability that must be corrected using additives, is attacked by strong mineral acids and absorbs polar solvents. Proper drying before forming is required Is.

Plastic parts made of this polyamide are used in the following industries:

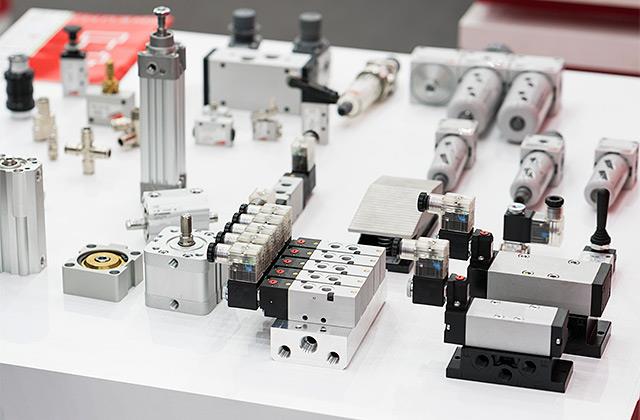

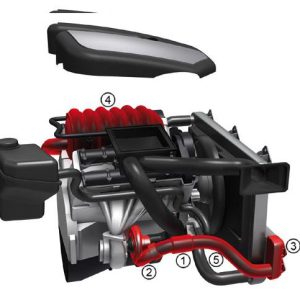

Auto Parts

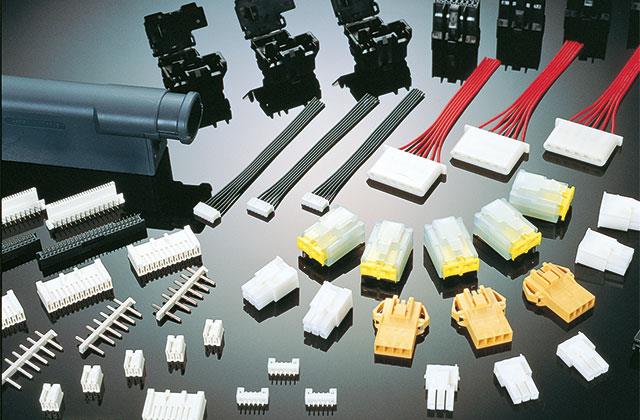

Electronics and electricity

Consumables for building construction

packing

Molded and extruded compounds have many applications as alternatives to metal parts, for example in car engine parts. Its lubricating properties make it useful for gears. Bearings make electrical insulation, corrosion resistance and nylon toughness a good choice for high-load parts in electrical applications. This application of Polyamide 6 has made it possible to use it as insulators, switching joints and cable connections.